Your trusted partner in high-quality packaging solutions for implantation devices

Your trusted partner for high-quality medical packaging solutions.

For efficient solution to manage low-volume batches typically related to research and development processes - Look no further! We specialize in delivering high-quality packaging technologies customized to meet the unique demands of R&D and Contract Research Organizations in the life science sector. With our one-stop shop approach, we provide not only machines, but also accessories, tooling and input materials, simplifying your packaging process and minimizing operational complexities.

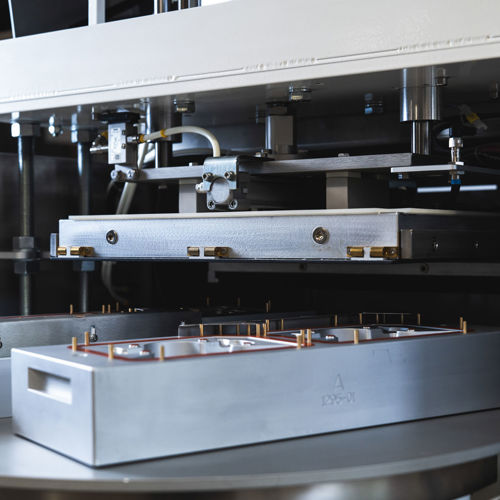

Maintaining efficiency and precision is important, especially in R&D environments where space constraints, flexibility, and control over the packaging process are essential. Machines in our Universal range form your packaging into the desired shape and size - and seal it with a protective layer, streamlining multiple packaging processes into a single, cost-efficient solution. This ensures you a flexible production setup, handling forming, filling, and sealing in one work cycle.

Ready to optimize your packaging process?

Contact us today to explore how our solutions can optimize your operations and elevate your productivity.

Consistent performance, lower investment.

Ensure consistent packaging quality, whileminimizing your investment costs. Our cost-effective machines deliver reliable performance, allowing you to quickly have new prototype blister packs ready for test and presentation.

In the developing fase You are able to quickly change your blister design at a very low cost, compared to any other blister packaging options available maintain uninterrupted production with maximum efficiency, Particularly with small batches.

Our solutions are tailored for scenarios such as sample productions or startup productions, where machines from Tommy Nielsen can easily integrate into larger operations later on. With minimal downtime between tool changes (typically 2-5 minutes), your production line stays agile and responsive to your packaging needs.

Ready when you need it.

Count on our machines to be ready whenever you need them. With their versatile and quick-change capabilities, they’re always prepared to handle your packaging requirements, ensuring smooth operations and timely delivery of your medical products.

Your advantages

Compact design

ideal for environments with limited space, e.g. for R&D and Contract Research Organizations (CRO)

Form, fill and seal:

One machine, multiple packaging processes

One-stop shop convenience

offering machines, tooling and foils

Low maintenance requirements

Flexible setup

that adapts to your needs ensuring efficiency and versatility

Always prepared and ready

for immediate use, ensuring seamless operation and efficiency

Minimal downtime

with fast and efficient tool changes, ensuring continuous and smooth production – typically within 2-5 minutes

Say goodbye to the hassle

of using high-volume equipment for low volume batches

Easy to operate

Tested in the market

for four decades